We Technomech are Designer, Developer, Manufacturer, Supplier of Sheet Metal Pressed Components, Sheet Metal Pressed Parts, Metal Sheet Pressed Components, Sheet Metal Parts, Sheet Metal Components, Sheet Metal Press Parts, Pressed Components, Pressed Parts and our setup is situated in Pune, Maharashtra, India.

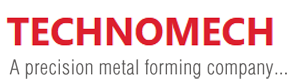

Customized to the requirements of the customer, as per their drawings / samples provided, we develop various operations on metal sheets like blanking, bending, trimming, forming, bidding, dimpling, piercing, extrusion etc.

Backed by its technical expertise, highly enthusiastic workforce and an array of power presses in varying range and a set of machines for secondary operations; in a short duration Technomech has attracted attention of buyers in Automotive Industry.

Sheet metal framing is a gathering of numerous correlative cycles that are utilized to shape sheet metal parts. At least one of these cycles is utilized to take a level sheet of malleable metal, and precisely apply distortion powers that adjust the state of the material. Prior to settling on the cycles), one ought to decide if a specific sheet metal can be framed into the ideal shape without disappointment. The sheet metal activities done on a press might be gathered into two classes, cutting ( shearing ) tasks and shaping tasks.

Industry wise Application of Sheet Metal Components / Parts Sheet metal shaping is utilized in pretty much every area of mechanical creation: Sheet Metal Processed parts are essential in each fragment

- Automotive industry

- Aircraft industry

- Home machine industry ( for example sinks, cooker hoods, coolers )

- Food industry ( for example cooking pots, canned merchandise )

- Electrical Components, etc...

Sheet metal framing is utilized for modern assembling in numerous areas – from vehicle entryway to metal can. In sheet metal framing, the last state of a section is produced using a level metal sheet. The ideal shape is accomplished through plastic misshapening, without going through any machining like processing. By and large, a specific measure of flexible deformity leads to spring-back which happens subsequent to framing is finished.

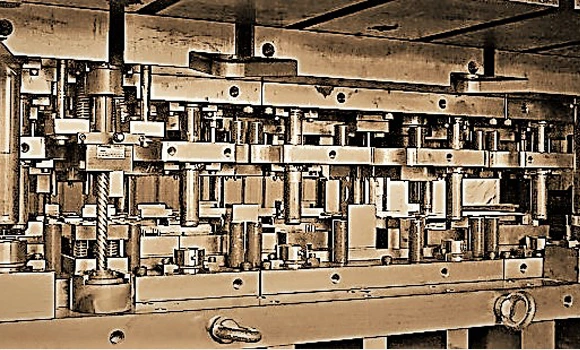

Metal Stepping Bites the dust We offer an assortment of stepping passes on appropriate for making parts for some applications. Metal stepping is the developmental course of forming and molding a workpiece of sheet metal between a punch and a bite the dust. Metal stepping passes on are the tooling appended to a stepping instrument. They control the workpiece and give the spine against which the workpiece is shaped when the punch applies pressure. Dissimilar to other bowing cycles, stepping assuages interior pressing factor in the metal so that there is no spring back or twisting in the wake of stepping. Metal stepping is normally utilized for an assortment of utilizations. It is an adaptable interaction fit for creating enormous volumes. Custom metal stepping kicks the bucket are different and can be arranged to make parts for various applications, including:

- Home Machines

- Fasteners ( washers, sections, metal clasps )

- Lighting

- Telecommunications

- Medical Gear

- Electronics

- High-security Locks

- Agricultural

- Furniture creation

- Ventilation ( conduit frill, downpour covers, channel holders, entryways, valves, and so forth )

Because of the repeatability, sturdiness, and accuracy of metal stepped segments, metal stepping is additionally great for the auto and clinical businesses where execution is vital. Various Sorts of Stepping Passes on There is an assorted scope of pass on types utilized for metal stepping, every one of which perform various tasks, like cutting, managing, indenting, blanking, puncturing, spearing, and shearing. Sorts of stepping bites the dust include:

- Blanking passes on

- Compound passes on

- Forming passes on

- Progressive passes on

Reformist passes on offer many advantages when contrasted with other kick the bucket types as they take into account high creation volumes. The reformist pass on stepping measure is fit for playing out various cutting and shaping tasks without a moment's delay and can rapidly deliver precise and predictable parts. We offer an assortment of pass on types with fast turnaround times to meet the necessities of your application. Technomech Pune group can convey quality sheet metal squeezed parts / Sheet metal Squeezed Segments for your altered need. Enquire with us for additional subtleties.